characterization of crystalline materials.Determination of unknown solids is critical to studies in geology, environmental science, material science, engineering and biology. X-ray powder diffraction is most widely used for the identification of unknown crystalline materials (e.g. A detector records and processes this X-ray signal and converts the signal to a count rate which is then output to a device such as a printer or computer monitor. When the geometry of the incident X-rays impinging the sample satisfies the Bragg Equation, constructive interference occurs and a peak in intensity occurs. As the sample and detector are rotated, the intensity of the reflected X-rays is recorded. These X-rays are collimated and directed onto the sample. Copper is the most common target material for single-crystal diffraction, with CuK α radiation = 1.5418 Å. K α1and K α2 are sufficiently close in wavelength such that a weighted average of the two is used.

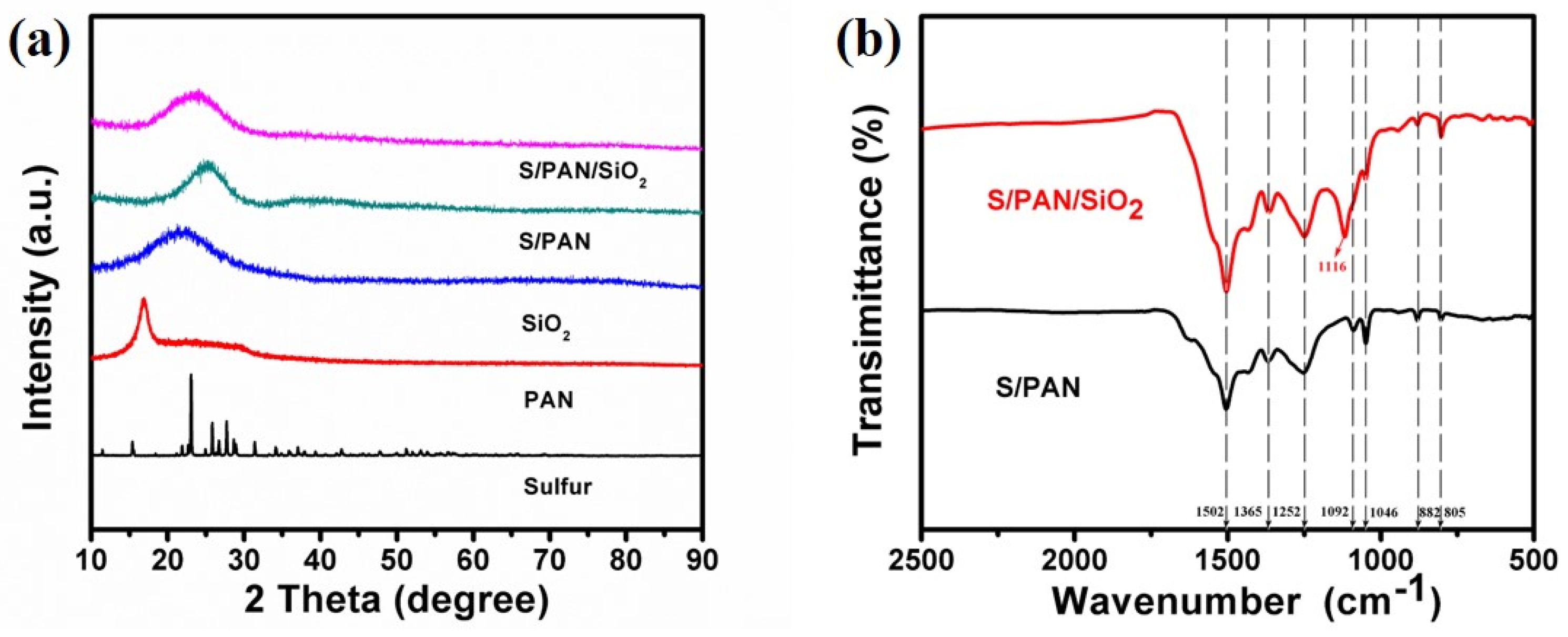

Filtering, by foils or crystal monochrometers, is required to produce monochromatic X-rays needed for diffraction. The specific wavelengths are characteristic of the target material (Cu, Fe, Mo, Cr). K α1 has a slightly shorter wavelength and twice the intensity as K α2. These spectra consist of several components, the most common being K α and K β. When electrons have sufficient energy to dislodge inner shell electrons of the target material, characteristic X-ray spectra are produced. Details X-rays are generated in a cathode ray tube by heating a filament to produce electrons, accelerating the electrons toward a target by applying a voltage, and bombarding the target material with electrons. X-ray Powder Diffraction (XRD) Instrumentation - How Does It Work?īruker's X-ray Diffraction D8-Discover instrument. Powder and single crystal diffraction vary in instrumentation beyond this. A key component of all diffraction is the angle between the incident and diffracted rays. These X-rays are directed at the sample, and the diffracted rays are collected. Typically, this is achieved by comparison of d-spacings with standard reference patterns.Īll diffraction methods are based on generation of X-rays in an X-ray tube. Conversion of the diffraction peaks to d-spacings allows identification of the mineral because each mineral has a set of unique d-spacings. By scanning the sample through a range of 2 θangles, all possible diffraction directions of the lattice should be attained due to the random orientation of the powdered material. These diffracted X-rays are then detected, processed and counted. This law relates the wavelength of electromagnetic radiation to the diffraction angle and the lattice spacing in a crystalline sample. The interaction of the incident rays with the sample produces constructive interference (and a diffracted ray) when conditions satisfy Bragg's Law ( n λ=2 d sin θ). These X-rays are generated by a cathode ray tube, filtered to produce monochromatic radiation, collimated to concentrate, and directed toward the sample. X-ray diffraction is based on constructive interference of monochromatic X-rays and a crystalline sample. X-ray diffraction is now a common technique for the study of crystal structures and atomic spacing.

Max von Laue, in 1912, discovered that crystalline substances act as three-dimensional diffraction gratings for X-ray wavelengths similar to the spacing of planes in a crystal lattice.

0 kommentar(er)

0 kommentar(er)